Large-Scale Vine Robots for Industrial Inspection: Developing a New Framework to Overcome Limitations With Existing Inspection Methods

Published in IEEE Robotics and Automation Magazine, 2024

Industrial facilities such as chemical factories, gas terminals, and power plants can contain kilometers of piping that require meticulous inspection for leaks and defects prior to operation. This is a costly and time-consuming process that sometimes requires dismantling sections of pipe. While current internal inspection devices such as borescopes, “pipe inspection gadgets,” rovers, and drones serve specific purposes, none can effectively maneuver through multiple bends with large diameter changes while pulling a tethered sensor. As a first step in addressing this need, we tackled the mobility challenge without a sensor, developing a 33-m-long, 1-m-wide, soft, inflatable vine robot for accessing hard-to-reach spaces in dangerous industrial facilities. We also investigated ways to mount sensors to large-scale vine robots, identified key challenges in doing so, and provide the framework for a potential solution. Our work addresses many modeling, design, and scaling challenges, including frictional properties, gravitational effects, pneumatic control, and portability. To validate the device’s capabilities, we conducted testing at a Bechtel facility in Houston, TX, USA. Our portable device successfully navigated a 24-m-long section of oil and gas piping, negotiating a 90° bend, a vertical section, a blockage, and an open chamber. Our work not only represents a substantial advancement in addressing current pipe navigation challenges but also establishes a new benchmark as the world’s largest soft robot, showcasing the effectiveness of pneumatic principles at large scales.

We tested the vine robot’s abilities to push and pull our tip mount design for camera equipment that would be vital in pipe inspection. This image was taken at UCSB.

We tested the vine robot’s abilities to push and pull our tip mount design for camera equipment that would be vital in pipe inspection. This image was taken at UCSB.

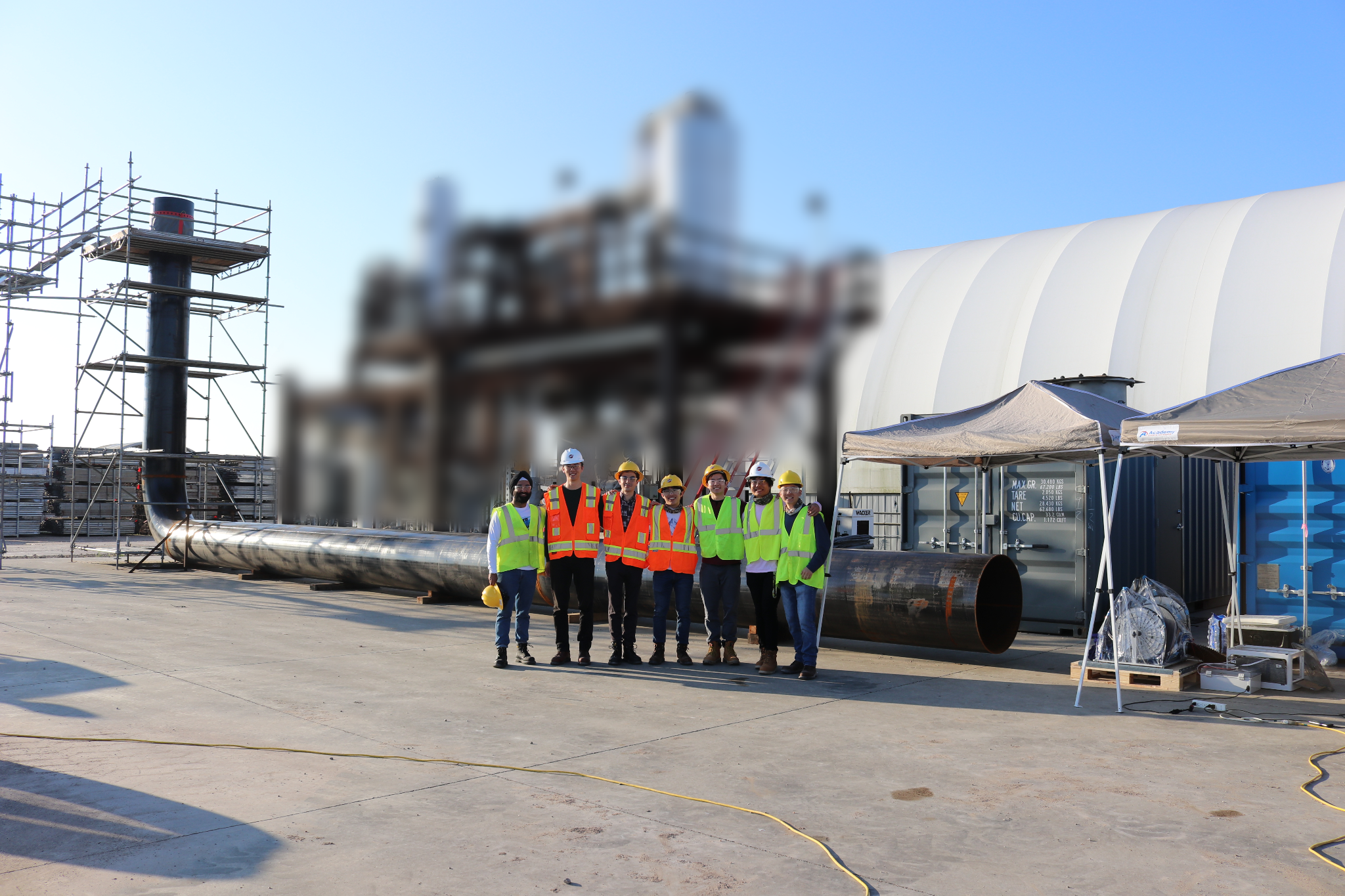

The vine robot in action! Starting from the base station beneath the tent in the lower right of the image, the vine robot grows through the length of the pipe and can be seen growing out of the pipe in the upper left. This image is from tests at Bechtel’s facility in Houston, Texas.

The vine robot in action! Starting from the base station beneath the tent in the lower right of the image, the vine robot grows through the length of the pipe and can be seen growing out of the pipe in the upper left. This image is from tests at Bechtel’s facility in Houston, Texas.

This paper collected all the results of a year-long capstone project at UCSB. In order from left to right are: Rajveer Oberoi, William Heap, Vedad Bassari, John Chen, Steven Nguyen (me!), Elvy Yao, and Steven Man.

This paper collected all the results of a year-long capstone project at UCSB. In order from left to right are: Rajveer Oberoi, William Heap, Vedad Bassari, John Chen, Steven Nguyen (me!), Elvy Yao, and Steven Man.

Recommended citation: W. E. Heap et al., "Large-Scale Vine Robots for Industrial Inspection: Developing a New Framework to Overcome Limitations With Existing Inspection Methods," in IEEE Robotics & Automation Magazine, vol. 32, no. 3, pp. 64-75, Sept. 2025, doi: 10.1109/MRA.2024.3487326.

Download Paper | Download Bibtex